Our Services

Prepress technicians set the foundation for successful printing production. They ensure that the proper format, appearance, and layout of text and images is set before the full print run of packaging materials or labels is completed. Prepress technicians take print or electronic files and scan or import them into specialized software, making colour, text, and digital image corrections as needed. They set up printing presses to produce film, plate or electronic proofs.

Rapid labels Prepress team are driven and happy to work directly with our customers to achieve the best possible results.

Contact us at prepress@rapidlabels.com.au Please to view our artwork checklist.

Please click here to view our artwork checklist.

We specialise is high quality, customised printing of Self Adhesive Labels and Flexible Packaging. Our philosophy is simple: to produce the highest quality product for our clients, by investing in the latest digital and conventional technology available in our market place today.

We believe in providing outstanding customer service from your inception with us, right through to product delivery to your door. We service an extensive range of industries, some of which are: Pharmaceutical, Natural Health, Food, Beverage, Wine, Brewing, Logistics and Chemical, just to name a few.

Shrink film is a plastic material which shrinks to the bottle with exposure to heat or steam. There are many benefits for using shrink film including the maximisation of space available for product branding and information, with a full 360° on your container or bottle. You also have versatility in your container or bottle choices as there are no longer application challenges to consider. Shrink film can also act as a tamper evident label when positioned over the cap. With the ink printed on the inside of the label, ink scuffing is a thing of the past and the labelling component of your packaging is fully waterproof, so it’s a great option for high moisture areas like the kitchen and bathroom.

As the theft rate continues to grow across Australia the need to protect your product becomes paramount. The major supermarket chains prefer Hi Value products such as Vitamins, Wine, Meat, and Infant formula to have security elements inserted into the packaging such as RF tags to protect against theft.

Ask our friendly team, how we can help protect your product against theft.

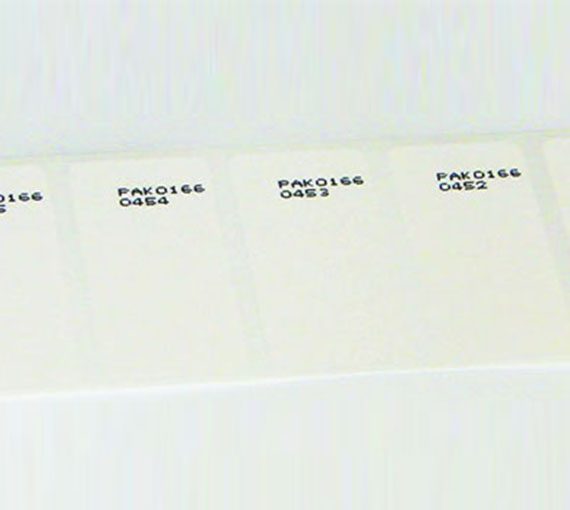

Rapid Labels offer sequential numbering on the backing sheet, a service which is used to ensure exact quantities per roll for batch integrity as well as line clearance procedures for guaranteed precision and accuracy.

Printing a sequential number on the backing sheet can also assist with monthly / yearly stock take. Partly used rolls of labels are generally not marked correctly when put back into storage, therefore it can make it harder to identify how many labels are left on the roll.

Printing a sequential number onto the backing sheet will give the exact amount of labels left over on the rolls ensure accurate stocktake numbers.

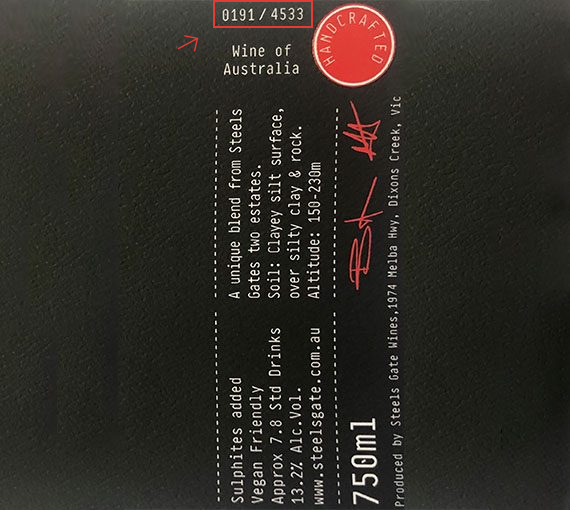

In short, variable data printing is a type of digital printing in which elements such as text, images, and graphics can change from one printed label to the next. This technique doesn’t stop or slow down the printing process and uses information from a database or PDF file.

Variable data is commonly used to make each individual product unique, it is commonly used for promotional purpose and it can also be used to make the product traceable if used to its full potential.

Screen printing is a printing technique where a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact.

Screen printing is most commonly used to create a Hi build varnish effect, this method is most effective due to the amount of ink lay down you can get from screen printing.

The projected value of Global Trade in Counterfeit and Pirated Goods is over $1.7 Trillion per year and two thirds of all counterfeit trade is from China. Australia and New Zealand’s cleaner environments together with high food and product safety standards have seen an increase in the demand and value of their products in China.

It’s for these reasons that Australian and New Zealand products are considered premium in China and make them a prime target for counterfeit operations.

As technology has improved, counterfeiting organisations are getting better at creating counterfeit products that are almost impossible for the customer to identify at the point of purchase.

Rapid labels has many options to protect your brand against counterfeiting. We are a leading in this specific area and offer a large range of options and we can tailor the perfect solution to suit your label volume and budget.

The addition of a clear High Build varnish to selected components on a label will mean the raised effect can be felt, and this will add impact to the presentation.

The Varnish can be raised significantly, can be coloured and tinted, and also applied in a pattern to the whole label – or a combination of these effects can be used to create a difference between your label and all the others.

A coating is basically designed to protect a label from damage by scuffing or friction during its useful working life. In addition many different finishes can be applied to the label to enhance its appearance and attract the consumer. These specialist varnishing can come in several finishes including gloss, matte, glitter, texture, uv responsive, scratchy, glow in the dark just to name a few. These inks can be used to highlight specific areas of a design.

The days of a simple flood coat varnish on a label have been left far behind, with high quality products emerging today ranging from high gloss and super matte to soft touch and rough texture coatings. A combination of different spot varnishes, for example, can create many contrasting and attractive effects, adding value to a brand by enhancing shelf appeal via its label.